E-CAM

Eco-friendly Circular Advanced Materials & Additive Manufacturing Lab

Bio Augmentation of Circular Materials

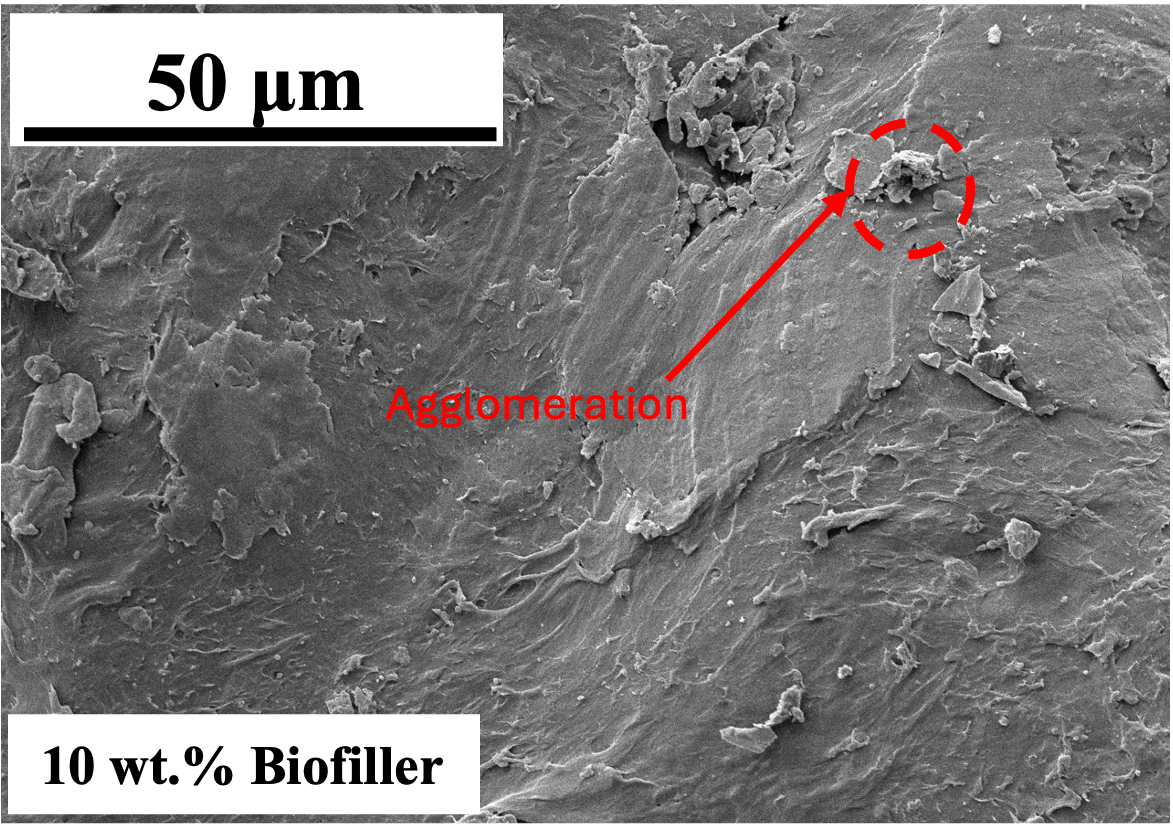

Considering the importance of sustainable living practices and recycling to lessen the harmful disruption and damage being done to the natural world and reduce waste sent to landfills and incinerators, and tackle global challenges like climate change and GHG emission, waste, and pollution, this research theme develops recyclable and sustainable feedstocks/materials using circular materials and via the conversion of waste, residue, biomass, and co-products into value-added products. To this end, this research uses biomass, natural fillers, fillers discarded by industries, plastic waste, recycled powders/pellets, and bio-based polymers and turns them into new 3D printing feedstocks. Also methodological investigations and advanced characterization are conducted to evaluate how processing and materials interaction affect final properties, and implant post-surface treatment to enhance performance outcomes for end-use applications. The development and use of green or recycled feedstock materials for low-cost AM to unlock the circular economy value chain causes a series of advantages, such as a reduction in disposal and production costs, a lower environmental impact, better performance, and versatility in different application sectors (engineering, medical, industrial, architectural, etc.).

Composite Fabrication

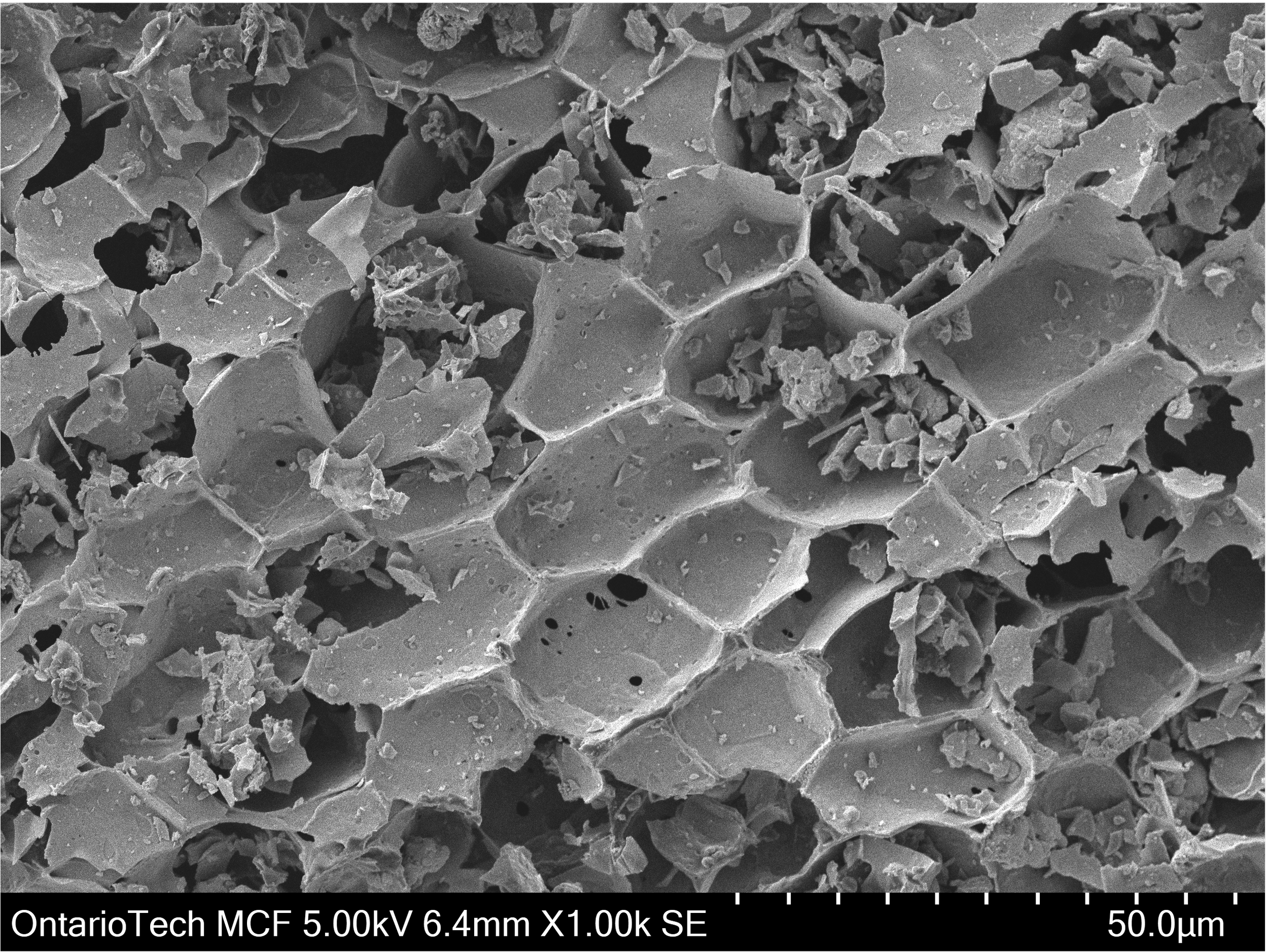

Fabricating polymer blend composites and utilizing pellet 3D printing are cutting-edge techniques in materials science. By blending different polymers, we create composites with tailored properties such as enhanced mechanical strength, thermal stability, and chemical resistance. These composites are then processed into various forms for specific applications. Pellet 3D printing, on the other hand, allows for the direct use of polymer pellets in the printing process, enabling the production of large-scale, cost-effective objects with customizable material properties. This innovative approach not only broadens the range of usable materials but also optimizes the performance and quality of the final product.

Part of Our Works...